Electrical Faults in Heavy Equipment: Which Manual Helps Diagnose It? (USA Guide) – Heavy-EquipmentManual.com

Electrical problems are one of the fastest ways to lose productive hours on a jobsite. In the USA, most breakdown calls I see (from technicians’ common field patterns) start with the same symptoms: no crank, warning lights, random shutdowns, or error codes that appear out of nowhere.

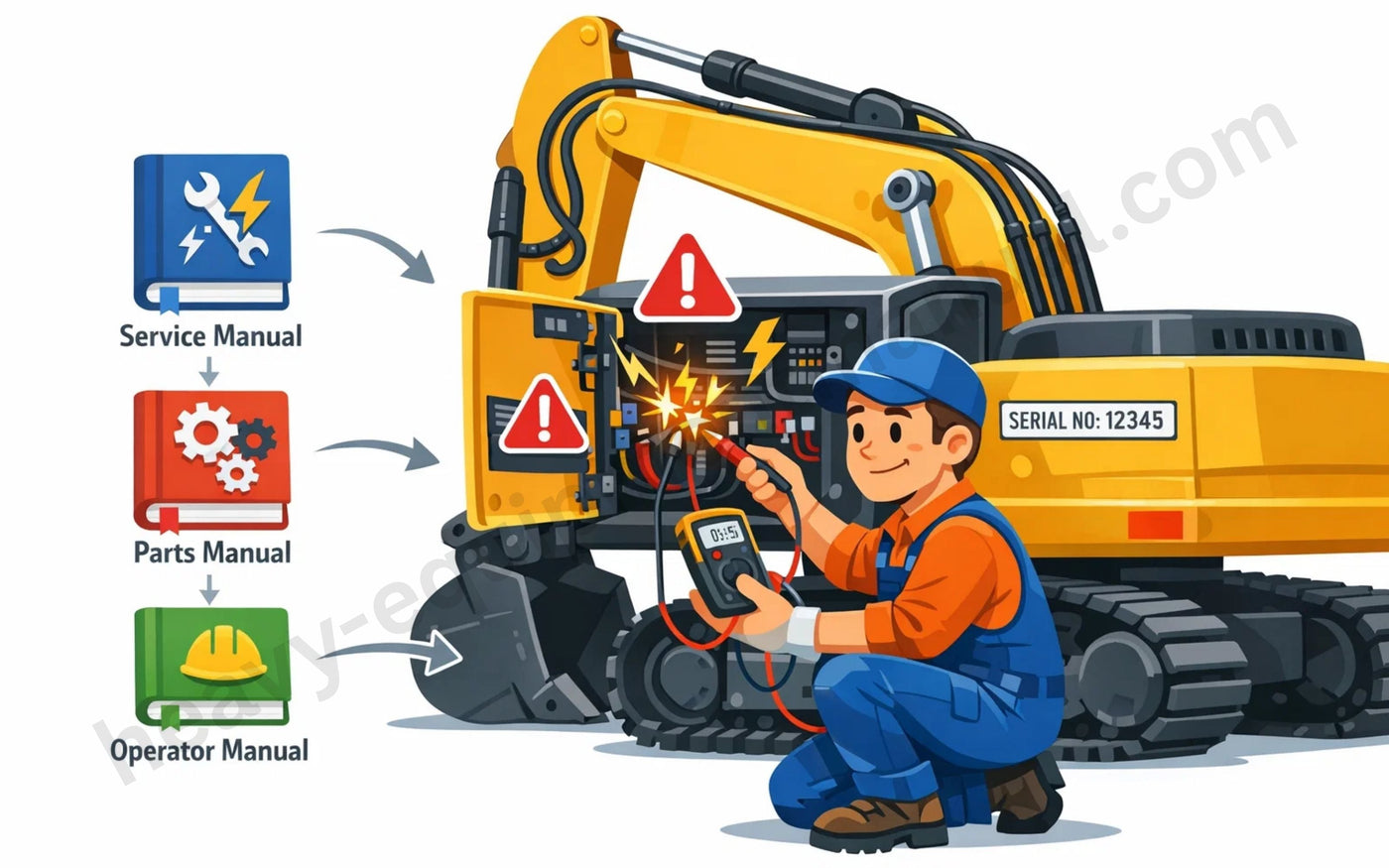

The truth is, electrical faults usually aren’t “mystery problems.” They become manageable when you use the right manual for the right job. A service manual will show you wiring paths and test steps. A parts catalog helps you identify the correct replacement component. An operator’s manual enables you to verify basics and safety checks before you go deeper.

This guide breaks it down clearly, which manual helps with which electrical issue, how to use it step-by-step, and what to do when diagnosing equipment in real-world US conditions (including dust, vibration, water exposure, winter starts, and long run hours).

If you’re looking for manuals in PDF format, start here: Heavy Equipment Manuals.

Why are electrical faults so common in US jobsite equipment

Heavy equipment electrical systems take constant abuse. In the USA, machines often run across:

-

Dusty sites (wiring connectors get contaminated)

-

Wet/muddy conditions (moisture creeps into plugs)

-

High vibration (grounds loosen, harness rub points wear)

-

Winter cold starts (battery performance drops, thick fluids strain starters)

-

Long hours (alternators and charging circuits get stressed)

Most faults come down to a few repeat causes:

-

Weak battery or poor battery connections

-

Bad ground points

-

Corroded connectors

-

Harness chafing (wire insulation rubbed through)

-

Failing sensors / intermittent ECM inputs

-

Charging system issues (alternator/regulator)

The 3 manuals that matter (and what each one is best for)

1) Service / Workshop / Repair Manual (best for diagnosis + fixing)

If you’re dealing with error codes, wiring problems, sensors, ECM issues, or charging system testing, this is the manual you want.

What it typically includes

-

Wiring diagrams + connector pinouts

-

Diagnostic steps and “test this first” procedures

-

Fault code lists + troubleshooting trees

-

Voltage/resistance specifications

-

Component removal/installation steps

-

Torque specs and adjustment procedures

✅ Use it when: your machine is throwing codes, shutting down, or acting intermittently.

2) Operator’s Manual (best for basic checks + safe operation)

This manual is often underrated. It helps with quick checks that solve a huge portion of “won’t start” calls.

What it’s good for

-

Basic troubleshooting by symptom

-

Fuse/relay locations

-

Warning light meanings

-

Safe battery disconnect steps

-

Daily inspection routines

✅ Use it when: you need fast verification (battery condition, fuses, safety interlocks).

3) Parts Catalog / Parts Manual (best for correct part ID)

A parts catalog won’t teach full diagnostics, but it prevents expensive mistakes by helping you order the right part.

What it helps with

-

Exploded diagrams of assemblies

-

OEM part numbers

-

Component location references

-

Variations by serial range/configuration

✅ Use it when: you’ve diagnosed the issue and need the correct sensor, relay, harness, or alternator.

Step-by-step: diagnosing common electrical faults (real-world process)

Here’s a simple field workflow that works on most equipment brands.

Step 1: Start with the symptom (Operator’s Manual)

Examples:

-

No crank

-

Cranks but won’t start

-

Random shutdown

-

Warning lights/error codes

-

Dead display / intermittent controls

Check:

-

Battery terminals are tight and clean

-

Battery voltage (quick check)

-

Main fuses and relays

-

Safety interlocks (seat switch, neutral switch, etc.)

If it’s still not clear → move to the service manual.

Step 2: Use the Service Manual wiring diagram like a map

A wiring diagram is not “too technical” if you use it correctly.

Do this:

-

Find the system (starter circuit / charging circuit / ECM power/lights)

-

Identify power source → fuse → relay → load → ground

-

Test in order:

-

Does power reach the fuse?

-

Does it leave the fuse?

-

Does the relay energize?

-

Does the voltage reach the component?

-

Is the ground path solid?

This cuts guessing dramatically.

Step 3: If you have codes, follow the fault tree (Service Manual)

Many techs waste time replacing parts because a code “sounds like” the failed item.

A better approach:

-

Read the code

-

Follow the test steps

-

Confirm wiring + connector condition

-

Confirm voltage/resistance values

-

Then replace only what’s proven faulty

Step 4: Use the Parts Catalog only after diagnosis

Once you know what failed (example: “coolant temp sensor” or “starter relay”), the parts catalog helps you order the correct one by:

-

Model

-

Serial number

-

Engine family variation

Real-world example: “No crank” on a US jobsite skid steer

Symptom: Key turns, dash lights up, but starter doesn’t crank.

Fast checks (Operator’s Manual + basic inspection)

-

Battery terminals tight?

-

Battery voltage acceptable?

-

Main fuse okay?

-

Neutral/seat safety switch engaged?

Then (Service Manual)

-

Confirm power at starter solenoid when key is turned

-

If no power: test starter relay circuit

-

Inspect ground strap resistance/connection quality

-

Check the harness rub point near frame rails (common vibration wear area)

Result: Often, the fix is a bad ground or corroded connector—not the starter itself.

Preventing electrical issues (simple habits that reduce downtime)

In the USA, most electrical faults are preventable with routine checks:

-

Clean battery posts and apply dielectric grease (as appropriate)

-

Inspect harness routing near hot spots and rub points

-

Re-seat key connectors during scheduled service intervals

-

Replace cracked loom and missing clamps before wires chafe

-

Keep fuse ratings correct (never “oversize” a fuse)

If you manage a fleet, keeping a printed “electrical quick check” sheet in the service truck saves hours.

Where to find the right manual (USA-focused)

If you want manuals that are easy to use in the field, look for PDFs that are:

-

Searchable text

-

Bookmarked

-

Printable without restrictions

-

Clear diagrams and wiring pages

You can browse by category on Heavy-EquipmentManual.com, and if you’re stuck choosing the right file, your best support pages are:

-

Download Help (email delivery + download troubleshooting)

-

FAQ (manual types, file format, delivery)

-

About Us (what you provide + how customers use it)

FAQs

Q1) What’s the best manual for electrical troubleshooting in heavy equipment?

A: For wiring, sensors, and fault codes, the service/workshop manual is best because it includes diagrams, pinouts, and diagnostic test steps. Start from Heavy-EquipmentManual.com to browse by brand and model.

Q2) Which manual includes wiring diagrams and connector pinouts?

A: Typically the service repair manual. Operator manuals may show fuse locations, but detailed wiring schematics and connector pinouts are usually in the service/workshop documentation.

Q3) My machine shows error codes—what should I do first?

A: Record the exact code, then use the diagnostic section in the service manual to follow the test steps. If you’re having trouble receiving or opening the PDF link, use Download Help.

Q4) Can a parts catalog help with electrical problems?

A: Yes—after diagnosis. A parts catalog helps you identify the correct relay, alternator, sensor, or harness by part number and diagram so you don’t order the wrong component.

Q5) What if I can’t find my equipment model manual online?

A: Use the site collections first, and if your exact model isn’t listed, contact the support email listed on the site pages. You can also reference the FAQ for manual types and how to request the right file.

Q6) Are these manuals usable for technicians in the USA?

A: Yes—PDF service manuals are commonly used in US workshops and field service trucks because they’re searchable, printable, and easy to access on laptops/tablets.